Technology

Open multideck fridges are vital to food businesses, offering easy access to chilled products without the hindrance of doors. Retailers often report sales uplifts when switching from glass-door fridges; however, traditional open-fronted multidecks provide drawbacks, with the main ones being an increase in energy costs and difficulty in maintaining maximum shelf-life. The key to maximising product shelf life is maintaining optimal temperature and humidity through heat removal, air circulation, and moisture control. If these factors are not controlled, food deteriorates quickly; with bacteria doubling in temperatures between 5°C-55°C.

Why Lucabo?

Innovators of aesthetic, sustainable & energy-efficient retail equipment; we develop temperature-controlled display solutions to decrease your energy consumption and increase your product quality. Our aero multidecks are powered by the patented award-winning Aircell technology - the world’s most effective refrigeration for food display.

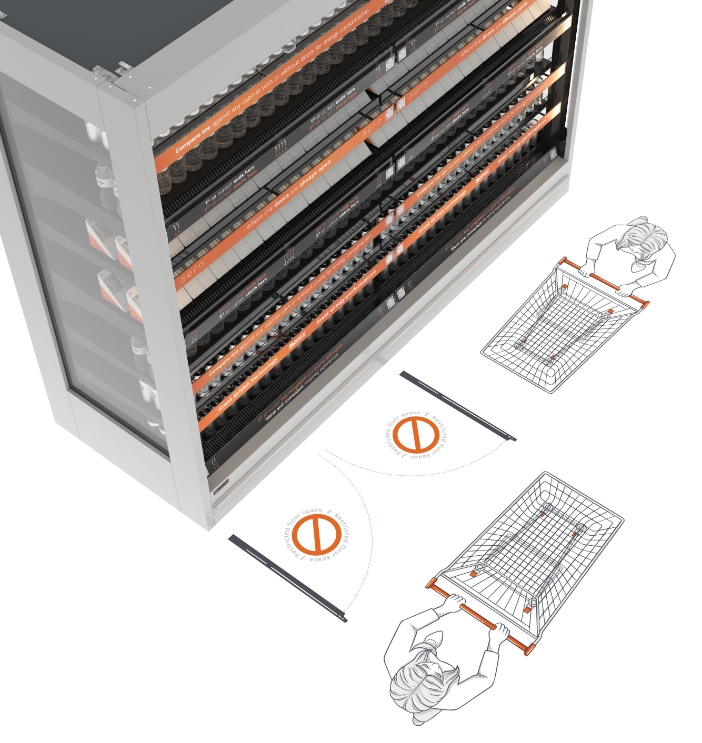

What is Aircell?

Aircell radically improves chilled airflow management to increase open-display refrigeration performance, enabling large volumes of food to be displayed in an easily accessible, precisely controlled environment with minimal energy. It provides better energy performance than cabinets fitted with shelf-edge air guides. Energy efficiency is crucial. By choosing aero, you are choosing units which have cold air curtains. This is where the velocity of the circulating cold air within the unit prevents the cold air from leaking and the temperature from rising. Every unit can retain the cold air within itself, despite being open-fronted. This prevents heat gain at the front of the unit, making it tolerant to higher external temperatures and negating the impact on ambient store conditions.

Making Convenience Stores Convenient

Energy bills can be significantly reduced, environmental targets can be met, and CO2 emissions can be lowered by over a tonne for every 2.5m aero cabinet installed (compared to a standard open-fronted cabinet). On average, supermarket chains can save over £20 million in energy costs and prevent over 50,000 tonnes of CO2 from being generated yearly. Aero addresses the modern day shopping experience, the current trend of closing cabinets with doors means congested shopping aisles and retailers potentially losing floorspace to allow for door openings. Aero is here to solve those problems, the Aircell technology has enabled the cabinet to keep produce at excellent temperatures whilst ensuring the aisle is still warm, more than that, we achieve amazingly low energy consumptions.

Lower Energy Use, Lower Carbon Footprint & Lower Costs.

Energy bills can be significantly reduced, environmental targets can be met, and CO2 emissions can be lowered by over a tonne for every 2.5m aero cabinet installed (compared to a standard open-fronted cabinet). On average, supermarket chains can save over £20 million in energy costs and prevent over 50,000 tonnes of CO2 from being generated yearly.

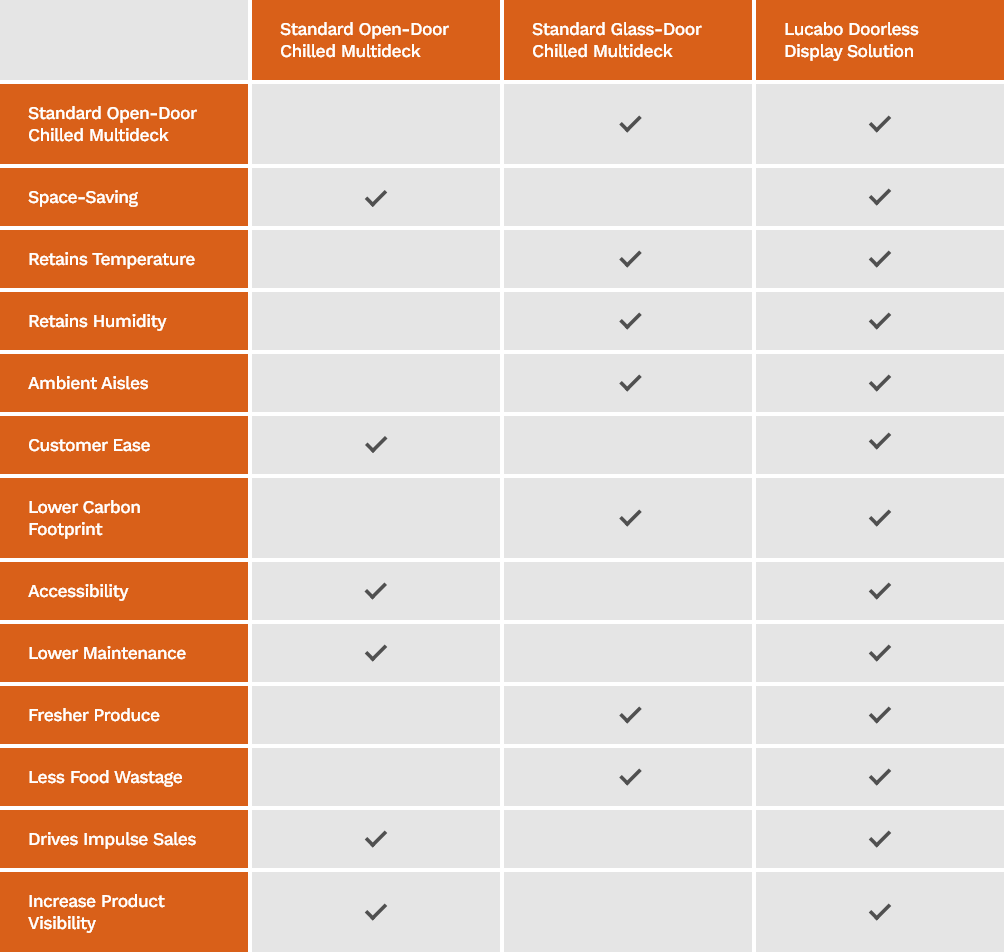

What Makes Lucabo Different?

Precise Temperature Control Preserves Food Quality.

Accurate And Consistent Temperature Control Throughout The Whole Cabinet Ensures That The Food Quality Is Maintained Wherever It Is Positioned, Maximising Shelf Life, And Reducing Wastage.

Better customer shopping experience

With chilled air staying in the cabinet, customers are not exposed to cold-aisle syndrome - this encourages longer browsing and gives more opportunities to buy.

Materials

We can process many materials in-house in our 60,000 sqft state-of-the-art facility, in-house, due to significant investments in machinery. We can create the most innovative and aesthetic cabinets from Polyurethanes, Plastics, Steel, Glass, and specialist composites.

Research and development

We invest heavily in Research and Development to ensure our equipment is as energy efficient as possible and creates the top conditions for preserving food quality. We know all equipment needs maintenance, and we pride ourselves on using our team’s vast servicing experience to ensure our products are engineer-friendly.

Quality control

The most crucial part of the process is ensuring that every product is worthy of the Lucabo brand. We have thorough end-of-line testing to ensure the highest quality standards at each stage of the process (from selection, customisation, and manufacturing, to delivery). Based on needs, the correct range of equipment will be found and matched to exact finishing requirements. State-of-the-art configuration software ensures a bill of materials is calculated to streamline time from quotation to production. Once an order is received, our bespoke ERP system starts calculating and ensuring all components are complete in time.